挤压丝锥(Forming Taps)

简介(Introduction)

挤压丝锥是一种用于内螺纹加工的切削工具,它通过塑性变形而非传统切削的方式在孔内形成螺纹。与普通切削丝锥不同,挤压丝锥不会产生切屑,而是通过材料的挤压和流动形成螺纹轮廓。这种加工方式不仅提升了螺纹的强度,还能提高表面质量和螺纹孔精度。由于无切屑生成,挤压丝锥减少了排屑处理的难题,特别适用于加工铝、铜及部分不锈钢等较软的金属材料。

Forming taps are a type of threading tool used for internal thread machining. Instead of cutting, they create threads through plastic deformation within the hole. Unlike conventional cutting taps, forming taps produce no chips; instead, they shape the thread profile through material displacement and flow. This process enhances thread strength, improves surface quality, and ensures higher thread hole accuracy. With no chip generation, forming taps minimize chip evacuation issues, making them especially suitable for processing soft metals such as aluminum, copper, and certain stainless steels.

挤压丝锥的优势(Advantages of Forming Taps)

✅ 螺纹强度高(High Thread Strength)

由于材料的挤压和冷作硬化(work hardening),螺纹的强度和耐磨性显著提高。

The thread strength and wear resistance are significantly enhanced due to material compression and work hardening.

✅ 表面光洁度好(Excellent Surface Finish)

挤压成形的螺纹表面更加光滑,减少了表面缺陷,提高了螺纹质量。

The surface of the formed thread is smoother, reducing defects and improving thread quality.

✅ 使用寿命长(Extended Tool Life)

挤压加工过程较温和,对丝锥的磨损较小,因此工具寿命更长。

The forming process is relatively gentle, resulting in less wear on the tap and longer tool life.

✅ 高效无屑加工(Chip-Free and Efficient Processing)

挤压丝锥适合大批量自动化生产,无需处理切屑,提高生产效率。

Ideal for high-volume automated production, as there are no chips to manage, improving efficiency.

应用领域(Applications)

挤压丝锥广泛用于高强度、高精度螺纹加工,适用于以下行业:

Forming taps are widely used in high-strength, high-precision threading applications, including:

• 汽车制造(Automotive Manufacturing)

用于发动机、变速箱、底盘等零部件的螺纹加工。

Threading for engine, transmission, and chassis components.

• 航空航天(Aerospace)

适用于飞机和航天器的轻量化金属加工,如铝合金材料。

Used for lightweight metal machining, such as aluminum alloys, in aircraft and spacecraft.

• 电子与家电(Electronics & Appliances)

适用于精密电子设备外壳和电器产品的螺纹加工。

Threading for precision electronic casings and home appliance components.

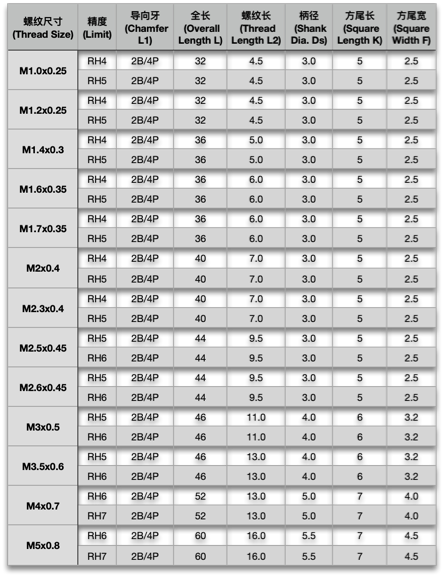

标准挤压丝锥简介(Standard Forming Taps Introduction)

标准挤压丝锥是一种无屑加工的内螺纹工具,它通过材料塑性变形形成螺纹,而不是切削材料,因此加工过程中不会产生切屑。与传统切削丝锥相比,挤压丝锥具有更高的螺纹强度、更好的表面质量以及更长的使用寿命。其加工方式特别适用于铝、铜、不锈钢等软质金属材料,并广泛应用于汽车、航空航天、电子、家电等行业的精密螺纹加工。

Standard forming taps are chip-free threading tools that create threads through plastic deformation of the material instead of cutting. As a result, no chips are generated during processing. Compared with conventional cutting taps, forming taps offer higher thread strength, superior surface quality, and longer tool life. This machining method is particularly suitable for soft metal materials such as aluminum, copper, and stainless steel and is widely used in automotive, aerospace, electronics, and home appliance industries for precision thread manufacturing.

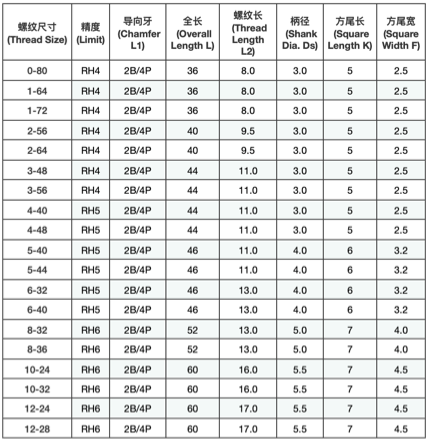

ANSI 标准挤压丝锥简介(ANSI Standard Forming Taps Introduction)

ANSI 标准挤压丝锥是符合 美国国家标准协会(ANSI) 规范的无屑内螺纹加工工具。它通过材料塑性变形形成螺纹,而非切削方式,因此在加工过程中不会产生切屑,提高了螺纹强度、表面质量和加工稳定性。ANSI 挤压丝锥具有标准化的螺纹形状、公差控制和尺寸规格,广泛适用于 铝、铜、不锈钢及其他软质金属材料 的高精度螺纹加工。

其主要特点包括:

✅ 符合 ANSI 标准,确保国际通用性和螺纹互换性

✅ 无切屑加工,减少切屑处理问题,提高生产效率

✅ 螺纹强度更高,材料经冷作硬化后更加耐磨

✅ 表面光洁度优异,螺纹质量更稳定

✅ 使用寿命长,降低刀具损耗,适用于大批量自动化生产

ANSI Standard Forming Taps are chip-free internal threading tools that comply with the American National Standards Institute (ANSI) specifications. They create threads through plastic deformation rather than cutting, ensuring chip-free machining, enhanced thread strength, superior surface quality, and improved processing stability. These taps follow standardized thread profiles, tolerance controls, and dimensional specifications, making them ideal for high-precision threading in aluminum, copper, stainless steel, and other soft metals.

Key Features:

✅ ANSI-compliant, ensuring international compatibility and thread interchangeability

✅ Chip-free machining, eliminating chip disposal issues and improving efficiency

✅ Higher thread strength due to material work hardening

✅ Superior surface finish for consistent thread quality

✅ Extended tool life, reducing wear and suitable for high-volume automated production

ANSI 标准挤压丝锥广泛应用于 汽车、航空航天、电子、家电、机械制造等行业,满足高精度、高强度的螺纹加工需求。

ANSI forming taps are widely used in automotive, aerospace, electronics, home appliances, and machinery manufacturing industries, ensuring high-precision and high-strength thread production.